“It’s the thing no one sees that leads to the results that everyone wants.” Craig Groeschel

I was driving home from a customer meeting this past week listening to Craig Groeschel’s leadership podcast. Craig was interviewing Jamie Kern Lima, founder of It Cosmetics (She’s amazing…Episode 107…I’m just saying). The topic was the challenges young businesses face scaling up. At one point during the conversation, Craig said, “It’s the things that no one sees that lead to the results that everyone wants.”

He’s right. It’s the stuff behind the scenes that separate the best from the rest. Take athletics for example. Individual athletes excel because they put in extra hours honing their skills. Same for musicians or chess players or computer programmers. Teams excel because they find little ways to jell more and function as one. Organizations excel because they continually solve problems for their customers and employees. Each of us has a choice — to show up and try to get a bit better every day or stay in place. Those choices and the small improvements add up.

For businesses at scale, it is about the process and improving processes. I was geeking out this weekend watching Elon Musk at the launch of Tesla’s Gigi Texas plant. He pointed out how many people can come up with a prototype. It takes some good engineering, creativity, and hard work. But building cars at scale is a whole other endeavor. It often requires both different orientations and different skills. For companies like ours to succeed, it is not about finding a whole bunch of people who will kill themselves to get things better. That’s not desirable, scalable, or sustainable. It’s about thinking about how the parts of the business come together; where the rub points are and synchronizing them, or identifying where the gaps are and filling them. It’s difficult. But doing that hard work, the things no one sees is exactly what will lead us to the results that everyone wants.

The timing of Craig’s message could not have been better as that morning we’d launched a revised internal order process. After 8 months of work among several internal teams, our JV partner, our IT supplier, over a dozen training sessions, and countless phone calls and emails, we launched the first in a series of changes last week.

What’s the big deal about some internal process? It isn’t sexy. It won’t sell more products or make any headlines. It won’t save our company money, at least not quickly. In fact, it may even cost us more in the short term as we may need to add people to help with the transition.

It’s a big deal for several reasons.

- It removes several pain points for our co-op customers and retail stores.

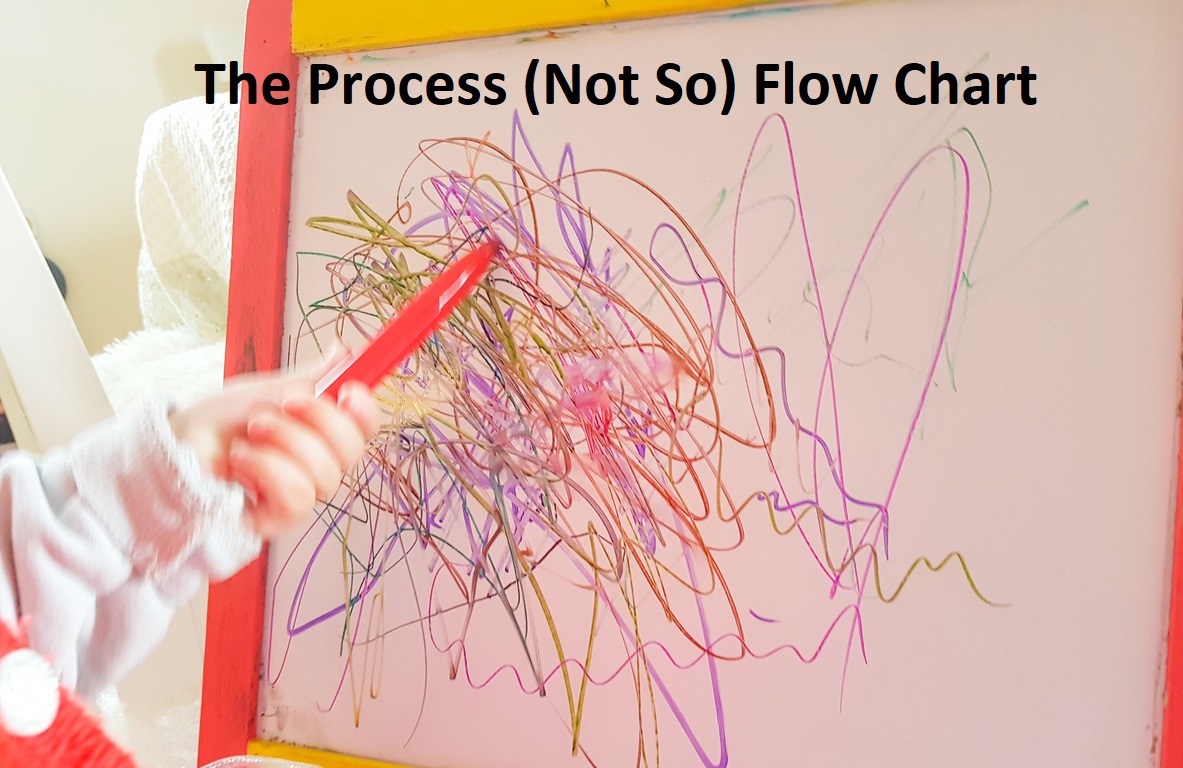

- It greatly simplifies the process. When we assembled the team and diagrammed the old “AS IS” process flow on a whiteboard, it looked like something a 3-year-old might come up with if you gave them a box of crayons and two shots of espresso – not pretty. Making us more efficient, the new process is simple and allows our teammates to spend less time re-entering data, correcting errors, or matching bills of lading to delayed invoices.

- The change was difficult. It involved several internal and external teams, any number of whom could have made it exponentially more difficult.

- We were able to get it done while things are going well. The challenge for us — and I’m guessing many businesses — is motivating change when things are going well. It is easy to say “Let’s fix the roof while its sunny,” but most of us would much prefer to play outside by the pool instead of slogging it out on the scorching hot roof.

Getting a not-very-sexy, very difficult change made involving a lot of different internal and external teams done when times are good is really hard. And we did it.

My personal thanks and congratulations go to the project lead, Amy Winstead, for her leadership, grit, and determination to overcome a huge number of obstacles and get us over the start line. Leadership matters, and it mattered a lot on this challenging project. Thank you also to our ERP Lead, Tami Elliot, as she was right there with Amy the whole time. Talk about someone doing the things behind the scenes to provide the results we all want! I’d also like to thank our partners at EFC Systems. They moved this up the priority list and got their part done on time. And when issues arose, they jumped right in. WinField also has been a strong partner, willing to work through the challenges our internal changes present to their system and their relationships with their suppliers. Finally, my thanks go to everyone throughout the administrative parts of the business for diving in and giving the new process a shot.

As Craig says, “It’s the things that no one sees that lead to the results that everyone wants.”

Onward!

Jeff